Digital Printing

Textiles

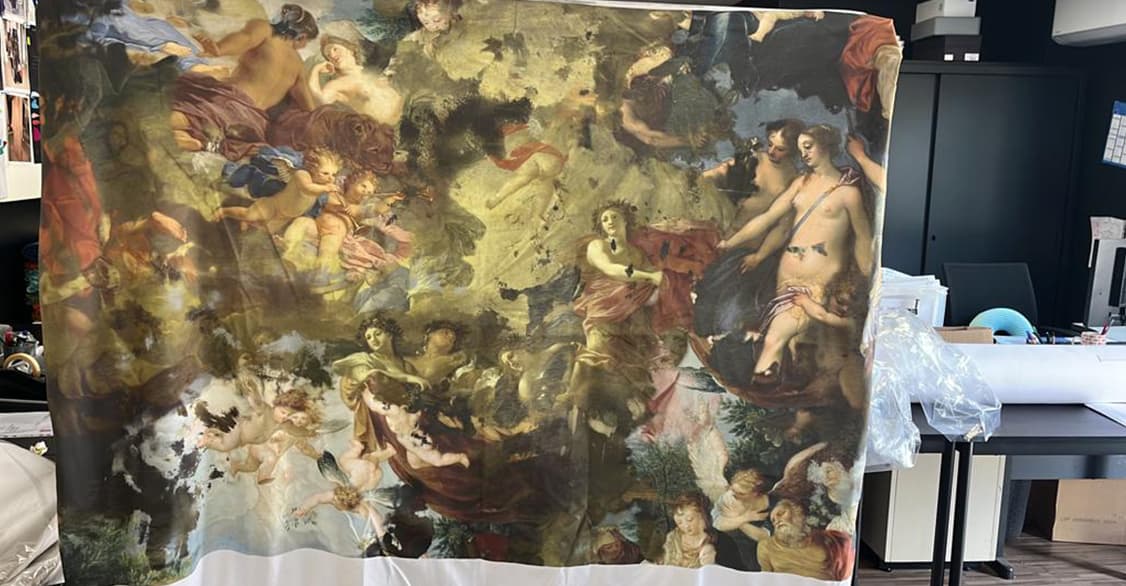

Personalised textiles and limited editions

Les Teintures de France is constantly equipping itself with ever more innovative equipment to offer its customers creative ideas that will enhance textiles, fabrics or accessories.

Last but not least, digital textile printing. This printing process uses special inks for all types of fabric and allows for high quality printing in colour or monochrome.

Digital textile printing is ideal for fabrics, leather, labels or advertising clothing. It offers many advantages over other printing methods. Thanks to this technique, Les Teintures de France has built up a loyal clientele in the fashion world by digitally printing fabrics for the biggest international high fashion brands.

All the advantages of

our Textile Printer

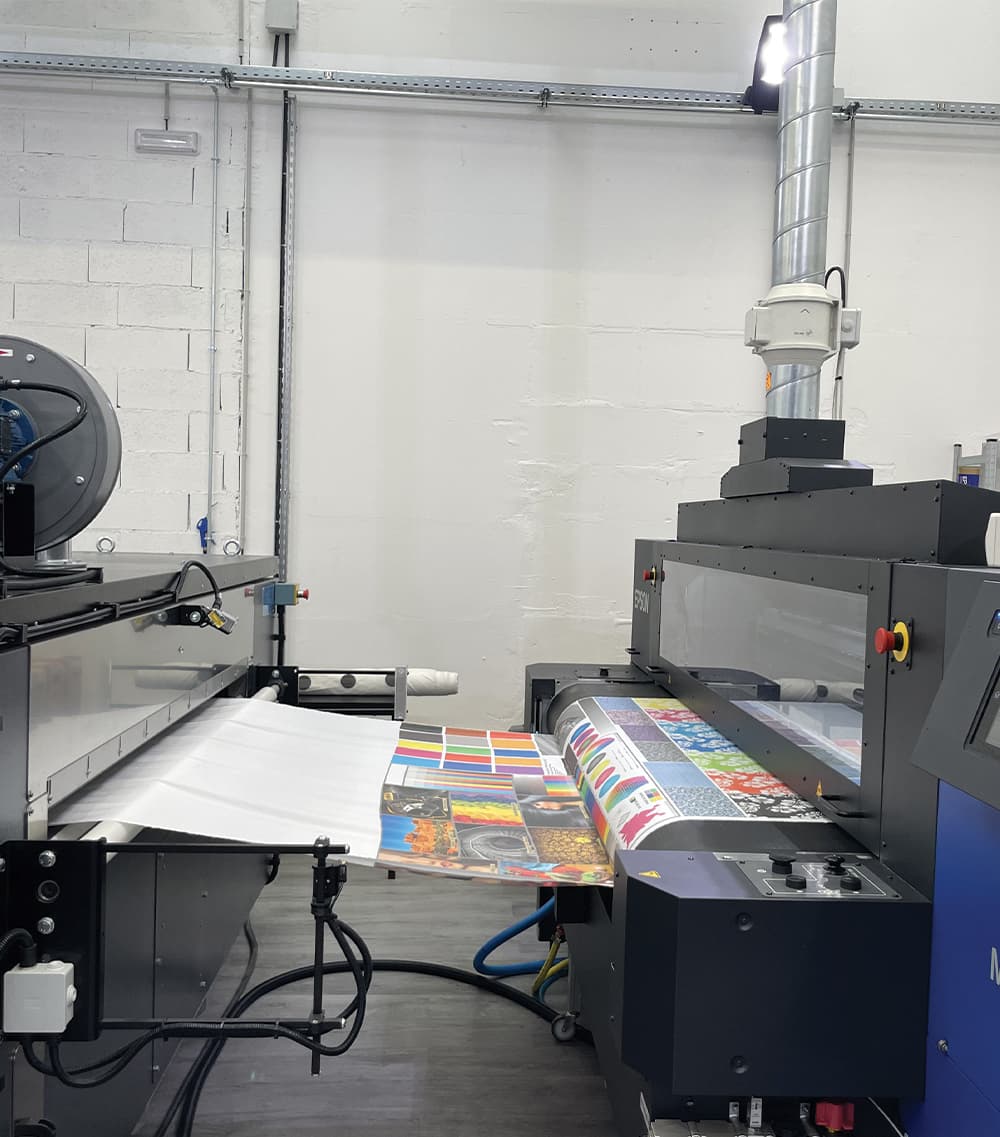

New Monna Lisa 8000 printer

With our new La Monna Lisa 8000 printer, we can now satisfy all of our customers’ expectations, offering them the highest quality print.

- Tiny fragments of fibres, threads, lint and buttons – which used to cause white spot printing defects – are now removed before the fabric is printed by a lint blower.

- Creases and wrinkles generated by the movement of the fabric on the printing bed and which cause unprinted white crease marks are mechanically eliminated by millimetre-level tension control.

- Print quality is more stable and does not drift during the print run, thanks to Epson’s Dynamic Alignment Stabilization (DAS) technology, in which the printhead nozzles are permanently aligned with each other.

- Print quality is also enhanced by the use of printheads that use a high-density print chip capable of generating more than 40 million precise dots and which use Epson’s micro-weaving technology to reduce grain.

- lThe Monna Lisa 8000 also has immaculate sustainability and environmental credentials. Epson’s Genesta inks are all certified eco-friendly by OEKO-TEX, Bluesign and GOTS..

- This printer uses 27% less water, significantly reduces the amount of effluent sent to sewage treatment plants and has an overall carbon footprint that is over 40% smaller than its rotary screen rival.